Composites: Papercrete

Composites: Papercrete

Composites are materials composed of other materials in combination, often with a matrix that binds together fibers of some kind. Papercrete gets its name from its components, paper and concrete, though it is technically composed of cement, not concrete. In papercrete, a composite of paper and cement, the cement makes up the binding matrix that holds the paper fibers together.

Paper is composed of a natural polymer, cellulose, the structure of which can be seen in the bottom image above and fibers of which can be seen in the top left and middle right images. The fibers get coated with cement, often Portland cement, and lend strength to the new material that could not be found in the cement alone. (Paper is not only made of cellulose, but it is a key component which makes papercrete possible. Aside from paper and cement, papercrete is also made with water and some form of sand or earth - other materials can be used as well, just like in concrete).

The material resulting from this mixture, papercrete, has excellent sound absorption, is flame and fungus retardant as well as bug and rodent repellent, and is relatively light. More flexible then rock or regular concrete, papercrete is useful in earthquake prone areas. Though not the best load-bearing material, papercrete is a great insulator. Like any composite however, the exact formula used to produce the material can alter the properties significantly. Adding sand or glass strengthens papercrete and makes it more flame retardant, but also increases its weight.

One of the beneficial things about papercrete is that almost any paper can be used to create it - cardboard, magazine paper, junk mail, newspaper, and other forms. Some work better than others but almost all can be used. Using waste papers such as these prevents them from entering landfills and allows paper to be recycled in a different way.

Downsides of papercrete include its lower strength and durability, as well as the fact that - as of now - there is no code or standardization to its manufacture or use, limiting the projects it can be used in. A fair amount of papercrete is made by individuals working on ‘do it yourself’ projects.

Sources: ( 1 - images 1, 2, 4, and 5 ) ( 2 ) ( 3 )

Image sources: (Middle left)

More Posts from T-sci-eng and Others

Students fortify concrete by adding recycled plastic

Adding bits of irradiated plastic water bottles could cut cement industry’s carbon emissions

Discarded plastic bottles could one day be used to build stronger, more flexible concrete structures, from sidewalks and street barriers, to buildings and bridges, according to a new study.

MIT undergraduate students have found that, by exposing plastic flakes to small, harmless doses of gamma radiation, then pulverizing the flakes into a fine powder, they can mix the plastic with cement paste to produce concrete that is up to 20 percent stronger than conventional concrete.

Concrete is, after water, the second most widely used material on the planet. The manufacturing of concrete generates about 4.5 percent of the world’s human-induced carbon dioxide emissions. Replacing even a small portion of concrete with irradiated plastic could thus help reduce the cement industry’s global carbon footprint.

Reusing plastics as concrete additives could also redirect old water and soda bottles, the bulk of which would otherwise end up in a landfill.

Read more.

Solar System: Things to Know This Week

10 Tools for the Armchair Astronaut, or How to Explore the Solar System from Home

At this very moment, spacecraft are surveying the solar system, from Mars, to Saturn, to Pluto and beyond. Now you can ride along to see the latest discoveries from deep space. For this week’s edition of 10 Things, we’ve assembled a toolkit of 10 essential resources for the desktop astronaut.

1. It’s Like Facebook, but for Planets

Or is it more of a Hitchhiker’s Guide to the Solar System? Whatever one calls it, our planets page offers quick rundowns, as well as in-depth guides, for all the major bodies in the solar system. Explore from the sun all the way to the Oort Cloud.

+ Peruse the planets + See how objects in the solar system stack up against each other

2. Keep Your Eyes on This One

If you still haven’t tried Eyes on the Solar System, you’re missing out. This free, downloadable simulation app lets you tour the planets and track the past, current and future positions of spacecraft–all in 3D. Eyes on the Solar System uses real NASA data to help you take a virtual flight across both space and time.

+ Prepare for departure

3. Dateline: Deep Space

With so much exploration underway, discoveries and new insights into the solar system come at a pace that borders on bewildering. NASA is rewriting the textbooks, literally, on a regular basis. Relax, though: there are several easy ways to stay up to date with what’s happening in space.

+ See the latest headlines + Stay connected on social media: Twitter, Facebook, Instagram + Find more top NASA social media accounts

4. Space? There’s an App for That

NASA offers phone and tablet apps for star gazing, pictures, news, 3D tours, satellite tracking, live NASA TV and many other kinds of info.

+ Start downloading + See other cool apps

5. A (Very) Long Distance Call

We’re in constant communication with spacecraft all over the solar system. The Deep Space Network is a global network of giant antenna dishes that makes it possible. With this online app, you can learn how it works – and even see which spacecraft are phoning home right now.

+ Deep Space Network (DSN) Now

6. Collect ‘Em All

Spacecraft 3D is an augmented reality (AR) application that lets you learn about and interact with a variety of spacecraft that are used to explore our solar system, study Earth and observe the universe. Print out the AR target and your camera will do the rest, making the spacecraft appear in 3D right in front of you. Learn more about these robotic explorers as they pop up on your desk, in your hand, or on your dog’s head.

+ Download Spacecraft 3D + See more cool 3-D resources from NASA

7. Ever Wanted to Drive a Mars Rover?

This site will give you a 3D look at the Mars Curiosity rover, along with some of the terrain it has explored. It will even let you take the controls.

+ Experience Curiosity

8. More E-Ticket Attractions

But wait, there’s more. NASA offers a variety of other fascinating (and free) online experiences, all based on actual data from real missions. Here are a few to explore:

+ Mars Trek + Vesta Trek + Moon Trek

9. The Universe Is Our Classroom

Studying the solar system makes for a compelling route into learning and teaching science, engineering and math. We have some great places to start.

+ Find resources for teachers + Build your own solar system with your classroom

10. Bring It on Home

After you’ve toured the far reaches of the solar system, you can always come home again. When you have spent time studying the harsh conditions on our neighboring planets, the charms of a unique paradise come into sharp focus, the place we call Earth.

+ Watch a real-time video feed from Earth orbit + See a daily global view of our planet from a million miles away + Hold the earth in your hands with the Earth Now mobile app

Discover more lists of 10 things to know about our solar system HERE.

Follow us on Tumblr for your regular dose of space: http://nasa.tumblr.com

Puritans, Goths, avant-garde artists, hell-raising poets and fashion icon Coco Chanel all saw something special in it. Now black, that most enigmatic of colours, has become even darker and more mysterious.

A British company has produced a “strange, alien” material so black that it absorbs all but 0.035 per cent of visual light, setting a new world record. To stare at the “super black” coating made of carbon nanotubes – each 10,000 times thinner than a human hair – is an odd experience. It is so dark that the human eye cannot understand what it is seeing. Shapes and contours are lost, leaving nothing but an apparent abyss.

apparently one whale years ago was observed doing this for hours and now more and more whales in the area are seen copying it so we think it’s a whole new behavior and it seems to be a response to shrinking food sources.

Instead of expending any energy actively hunting, the whale just holds its mouth open wherever fish are being hunted by birds. To escape the birds, the fish try to hide in the whale’s mouth because it’s a darker area that looks like shelter. …They’re turning into giant, sea-mammal pitcher plants.

https://onlinelibrary.wiley.com/doi/epdf/10.1111/mms.12557?referrer_access_token=bXLTS5BeSw_vlIKHkM0bYIta6bR2k8jH0KrdpFOxC654HjreJ8D19K86UreR5JPsSRb0CuGhiJSV1L1ht-N1Gf_K_1a9MREFzQGU9oJDNctsKDin_HXcYEdsLg3EbcTl

Due to the Mandela Effect, we remember things that didn’t happen or exist. Get the answer and why in our NEW VID: https://youtu.be/hvu4D1jngCY

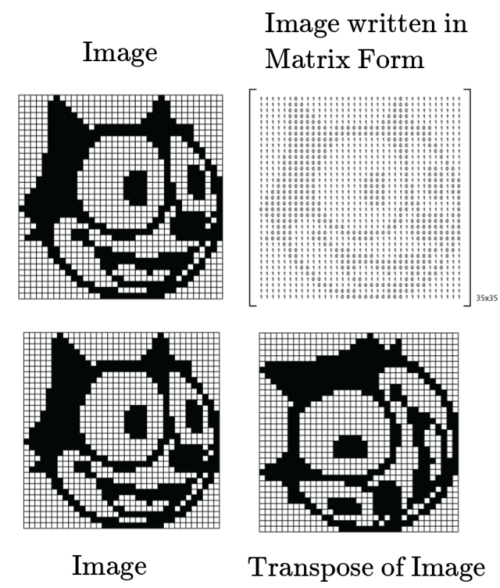

On the transpose of a matrix

In this post, I would just like to highlight the fact an image can be represented in a matrix form and matrix transformations such as transpose, shearing, scaling, etc, from an image processing point of view are purely physical !

Check out this article from the klein project if this post interested you.

Have a great day!

* Interactive Felix the cat and matrix

Science Fact Friday: Bird lungs! Just like every other part of a bird, they’re weird.

This gif shows the path of a single breath, but the circuit holds 2 breaths at a time. So when the bird inhales, the just-inhaled breath goes through Inhalation 1 while the previous breath goes through Inhalation 2. Rinse, repeat. Thus, the lungs are constantly receiving oxygen - in mammals, our oxygen content dips slightly between inhalations because there’s no fresh air coming in. We also don’t empty 100% of our lung volume so some air is “stale” even during an inhalation.

Support Science Fact Friday on Patreon!

Transcript below the break.

Keep reading

Alloys: Steel

According to Dictionary.com, steel is “any of various modified forms of iron, artificially produced, having a carbon content less than that of pig iron and more than that of wrought iron, and having qualities of hardness, elasticity, and strength varying according to composition and heat treatment: generally categorized as having a high, medium, or low-carbon content”.

Perhaps the most well known alloy around, as well as one of the most common materials in the world, steel is essentially iron with a small percentage of carbon (and, on occasion, one or more other elements). Not enough carbon and you’re stuck with wrought iron, too much carbon and you get cast iron. The graph above is a binary iron-carbon phase diagram that goes from zero percent carbon to about 6.5 percent, illustrating the various phases that can form.

Steel has been known about since ancient times, some pieces dating back to 1800 BC, but it was the invention of the Bessemer process during the industrial revolution that really popularized the alloy. (Technically, similar methods had been used before, particularly in China and Japan, but Henry Bessemer invented the modern method, industrializing it and obtaining a patent in 1856.)

Mainly used in construction, the alloy has been used for almost every possible application: from office furniture to steel wool, from bulldozers to washing machines, and from wires to watches, the possibilities are pretty much endless. Steel is also one of the world’s most-recycled materials, able to be used more than once, with a recycling rate of over 60% globally.

The addition of carbon allows the steel to be stronger than the iron it’s made from. Adding nickel and manganese increases its tensile strength, chromium increases hardness and melting temperature, and vanadium also increases hardness while making it less prone to metal fatigue. Stainless steel has at least eleven percent chromium, whereas Hadfield steel (which resists wearing) contains twelve to fourteen percent manganese. Check out these links for more information on the effects of adding certain elements.

Sources: 1 (top images), 2 (bottom images)

We started looking at fluctuating loads last time - that is, loads that feature some combination of non-zero mean and alternating stresses - and how to account for them using a Goodman diagram. Let’s re-examine the bracket design problem we did earlier. This time, instead of a fully-reversed load, we’ll assume a fluctuating load with a mean force of 200 lbs, a minimum force of 50 lbs, and a maximum force of 350 lbs. We’ll say the dimensions of the bracket are those we calculated earlier that could handle the fully reversed load. (Problem adapted from Machine Design: An Integrated Approach, 4th Ed., by Robert L. Norton.)

Most of the calculations we did earlier will still hold. We won’t need to recalculate the endurance limit or stress concentration factors. The only new things we need to do are calculate the mean and alternating stresses and the new safety factors.

First step is to calculate the mean and alternating force.

From here, we get the mean and alternating moment.

We’re dealing with a situation of simple bending, so we can calculate mean and alternating stress using the basic bending stress equation.

The geometry of the part hasn’t changed, so we’ll apply the same stress concentration factors that we used before.

Great. We’ve got our new stresses. Now we need to figure out safety factors. As we mentioned earlier, this is now a slightly more complicated proposition. Which safety factor is appropriate will depend on how the alternating and mean stress behave in relation to each other. The possible failure states are shown as points A, B, C, and D on the Goodman diagram for this situation.

We’ll step through all the possible situations one by one using the new stresses we calculated and the endurance limit we got earlier.

Case 1: Constant alternating stress, variable mean stress.

Case 2: Variable alternating stress, constant mean stress.

Case 3: Alternating and mean stress are proportional to each other.

Case 4: Alternating and mean stress vary independently.

We take the worse case, with the failure state F being as close as possible to the current stress situation.

Our design will survive all four cases. Note that Case 4 is always the most conservative case - if you don’t know what your stresses are going to do, this is the one to go with.

Hackaday Useful Tools Links

So I am an avid reader of Hackaday for a long time now and they have been putting out a lot of great introductions to tools and processes to get makers up to speed on the resources that are available. This is just a splattering of links that I have found lately that you guys might be interested in.

DC Motors

Lessons in Small Scale Manufacturing

Grinding Gears: Figuring out gear ratios

Tools of the trade: Injection Molding

Are todays engineers worse?

How to nail a technical presentation

Tools of the trade: Vacuum Forming

The Art and Science of Bending Sheetmetal

A how-to of designing, fab, and assembly with structural framing systems (t slot)

Machine learning foundations

A machine shop in a box

How to: Cold resin casting

Join the GUI generation: Qtcreator

Do you guys have any other great resources that you’d like to share and/or are you enjoying this type of content?

-

codeandcanvas liked this · 2 years ago

codeandcanvas liked this · 2 years ago -

ghostoftheturtlelord reblogged this · 2 years ago

ghostoftheturtlelord reblogged this · 2 years ago -

ogpenguinuniverse reblogged this · 2 years ago

ogpenguinuniverse reblogged this · 2 years ago -

sex-icon-martinelli liked this · 2 years ago

sex-icon-martinelli liked this · 2 years ago -

charlesh55 liked this · 2 years ago

charlesh55 liked this · 2 years ago -

exlioncub liked this · 2 years ago

exlioncub liked this · 2 years ago -

mauer186 liked this · 2 years ago

mauer186 liked this · 2 years ago -

tits-n-butts reblogged this · 2 years ago

tits-n-butts reblogged this · 2 years ago -

tits-n-butts liked this · 2 years ago

tits-n-butts liked this · 2 years ago -

nice-to-know liked this · 2 years ago

nice-to-know liked this · 2 years ago -

engagingthesenses liked this · 2 years ago

engagingthesenses liked this · 2 years ago -

iamtherapemannow liked this · 2 years ago

iamtherapemannow liked this · 2 years ago -

ionicchains liked this · 2 years ago

ionicchains liked this · 2 years ago -

ginrummy68 reblogged this · 2 years ago

ginrummy68 reblogged this · 2 years ago -

ginrummy68 liked this · 2 years ago

ginrummy68 liked this · 2 years ago -

smol-stardust liked this · 2 years ago

smol-stardust liked this · 2 years ago -

belovedbucket liked this · 2 years ago

belovedbucket liked this · 2 years ago -

comtedemoney liked this · 2 years ago

comtedemoney liked this · 2 years ago -

rdx-dcm liked this · 2 years ago

rdx-dcm liked this · 2 years ago -

been-here-since-76 liked this · 2 years ago

been-here-since-76 liked this · 2 years ago -

theresa-of-liechtenstein liked this · 2 years ago

theresa-of-liechtenstein liked this · 2 years ago -

swordsagedachsie reblogged this · 2 years ago

swordsagedachsie reblogged this · 2 years ago -

swordsagedachsie liked this · 2 years ago

swordsagedachsie liked this · 2 years ago -

luckisnotadumpstat liked this · 2 years ago

luckisnotadumpstat liked this · 2 years ago -

materialsscienceandengineering reblogged this · 2 years ago

materialsscienceandengineering reblogged this · 2 years ago -

kholexcx liked this · 6 years ago

kholexcx liked this · 6 years ago -

t-archnstruct reblogged this · 7 years ago

t-archnstruct reblogged this · 7 years ago -

t-sci-eng reblogged this · 7 years ago

t-sci-eng reblogged this · 7 years ago -

now-what-where-why liked this · 8 years ago

now-what-where-why liked this · 8 years ago -

nope-youmad liked this · 8 years ago

nope-youmad liked this · 8 years ago -

thenanoscientist-blog liked this · 8 years ago

thenanoscientist-blog liked this · 8 years ago -

jaunit reblogged this · 8 years ago

jaunit reblogged this · 8 years ago -

jaunit liked this · 8 years ago

jaunit liked this · 8 years ago -

corprus reblogged this · 8 years ago

corprus reblogged this · 8 years ago -

beefyhitman liked this · 8 years ago

beefyhitman liked this · 8 years ago -

evgeshanik liked this · 8 years ago

evgeshanik liked this · 8 years ago -

adhdchemist-blog reblogged this · 8 years ago

adhdchemist-blog reblogged this · 8 years ago